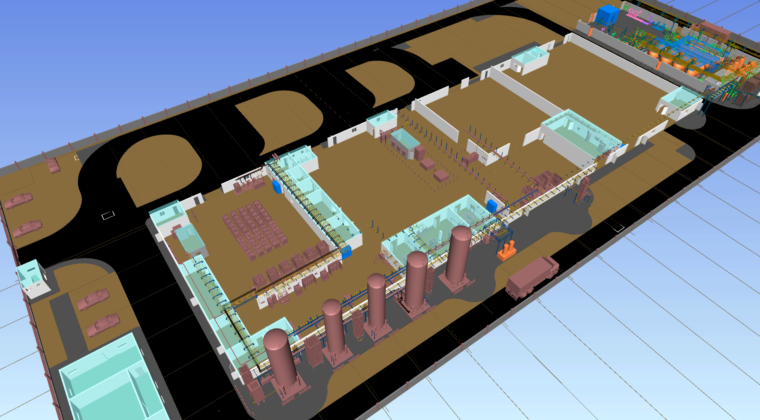

A major part of our latest project execution strategy is to prepare 3D Modelled Cylinder Filling Plant for any new cylinder filling plant we engineer.

The key benefits of this approach includes;

- 3D Modelled Cylinder Filling Plant provides the client and all stakeholders with a clear view of the future plant. This includes the ability to ‘walk through’ the virtual plant.

- Ensures optimised product flow and ergonomics at the design phase.

- Enables IGAS to prepare very detailed layouts and equipment lists for the plant (at design phase), including but not limited to;

- Tank farm layout.

- Pipework routes and distances.

- Cable routes and distances.

- Filling hall layout ensuring optimised product flow, efficiency and ergonomics.

- Ensures equipment selection (dimensions) are designed to “fit” with no clashes.

- Detailed information eases the installation phase.

https://igph.net/2020/01/igph-video/

IGPH Ltd (Industrial Gas Projects House), comprising iGas Technology Solutions, m-tech GmbH, Filltech GmbH, Aeroflex and Krytem GmbH are European designers and manufactures of Cylinder Filling and Gas Solutions.

Each member of IGPH brings elements of the total solution which can be integrated into a total turnkey plant solution or provided as standalone equipment.

Applications served and expertise provided includes;

- Turnkey plant (process, mechanical and electrical) design & engineering

- Manufacture and installation (globally)

- Industrial, Medical, Speciality Gas and Refrigerant Cylinder Filling Solutions

- Mono and mixture gases cylinder filling solutions

- Cryogenic equipment and cylinder filling solutions

- Trailer filling and decanting system

- Gas generation systems

- Pressure reduction and gas supply systems

- CO2 recovery, liquefaction and filling solutions

- Fixed and mobile (containerised) plant

- Manual, semi-automatic and automatic plant