Proportional operated, pressure controller is the solution to your “drifting” pressure controllers, resulting in improved productivty.

Our solution:

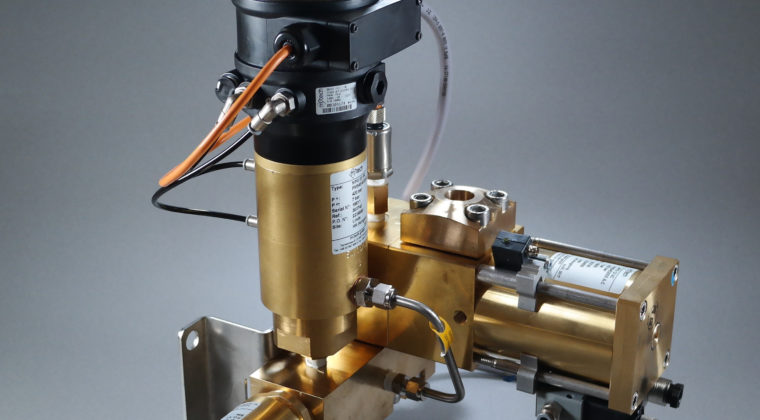

Fully integrated, Proportional operated, pressure control module comprising; Inlet particle filter, automatic, proportional pressure controller, outlet transmitter and pressure relief valve.

Function:

Outlet (P2) pressure is continually monitored, changing the position of then proportional valve therefore maintaining a stable out (P2) pressure, regardless of inlet pressure (P1) or ambient conditions.

Flexibility:

As is always the case with mtech GmbH / IGPH Group, our solutions are designed / manufactured to meet the exacting needs of our clients, therefore, this unit is available in a variety of set pressures and gas types.

Specification of a recent supplied unit;

- Service – Oxygen

- Design pressure – 420 bar

- Nominal Inlet pressure – 230 bar

- Set (P2) pressure – 165 bar

- Pressure relief valve set – 173 bar

Documentation / approvals:

All valves within the solution are adiabatically shock tested be either CTE or BAM for use within Oxygen at 420 bar (600 bar version also available).

All component valves within the solution, including the final module are fully assembled and tested within our ISO 7 cleanroom.

https://www.m-tech-gmbh.de/en/gas-filling-systems/

IGPH Ltd (Industrial Gas Projects House), comprising iGas Technology Solutions, m-tech GmbH, Aeroflex, Krytem GmbH and POLO Italia are European designers and manufactures of Cylinder Filling and Gas Solutions.

Each member of IGPH brings elements of the total solution (from concept to completion) which can be integrated into a total turnkey plant solution or provided as standalone equipment.

Applications served and expertise provided includes;

- Industrial, Medical, Speciality Gas and Refrigerant Cylinder Filling and Gas Solutions

- Mono and mixture gases cylinder filling solutions

- Turnkey plant (process, mechanical and electrical) design & engineering including safety studies based on IEC 61511, encompassing HAZOP, SIL, LOPA and ATEX / Hazardous Area evaluation and designs.

- Manufacture and installation (globally)

- Cryogenic equipment and cylinder filling solutions

- H2 Trailer filling and decanting system

- Gas generation systems

- Pressure reduction and gas supply systems

- CO2 recovery, liquefaction and filling solutions

- Fixed and mobile (containerised) plant

- Manual, semi-automatic and automatic plant

- Pressure Temperature, Gravimetric and Mass Flow filling techniques